How Can Mine Action Improve the Management of Free from Explosive (FFE) Items?

By Roly Evans [ Geneva International Centre for Humanitarian Demining ]

CISR JournalThis article is brought to you by the Center for International Stabilization and Recovery (CISR) from issue 26.1 & 2 of The Journal of Conventional Weapons Destruction available on the JMU Scholarly Commons and Issuu.com

Assessing and making items free from explosive (FFE) are among the most dangerous things we do in mine action and are perhaps the least regulated. Mine action operators use items that have been made FFE or INERT for training and demonstration purposes. However, the sector does not really have sufficient procedures or qualifications to assess items as certified free from explosive (CFFE), or to make items FFE/INERT. Assessing or making items FFE are explosive processes and should be treated as such more consistently within the mine action sector. This article will outline the current state of play concerning FFE items in mine action, some of the problems involved, and suggest some potential options for consideration.

The Requirement for FFE Items

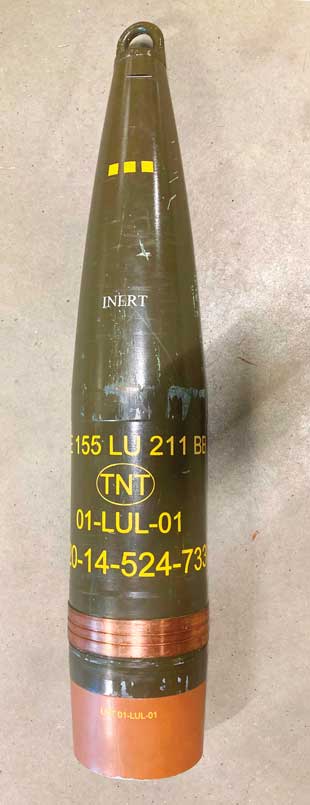

Figure 1. An INERT LU 211 BB 155mm projectile. Note the clear INERT marking on the ogive. Rigorous marking of FFE items is essential. Some items in the sector are simply inadequately marked with an indelible permanent marker pen. Image courtesy of Danish EOD and Search Center.

The humanitarian mine action (HMA) sector uses items of explosive ordnance (EO) that are CFFE, or INERT1 for a range of reasons (INERT and FFE are interchangeable terms with the same essential meaning). Foremost among these is the need to provide items for training, not only to show students what different categories, sub-categories, and models of EO2 look like, but also to provide items for realistic field exercises.3 For example, training deminers to find a specific type of mine will typically involve some form of INERT substitute target. An anti-personnel (AP) or anti-vehicle mine is made FFE, but as many metal components as practicable are retained.4 In this way, the item keeps the electromagnetic signature of the mine for detection purposes but does not pose an explosive hazard to the trainee. Substitute targets are also used throughout the day on demining sites by trained deminers in order to calibrate and re-calibrate their detectors as required.5 Given that manual demining requires thousands of staff to be trained and re-trained without immediate risk, and that each demining site needs a substitute target for its test pit,6 the need for inert targets for demining operations is arguably substantial. While inerting items involves an “inherent risk,”7 it could be claimed that not inerting items and therefore not having targets with a high degree of fidelity also poses a risk to deminers. Without such high-fidelity substitute targets, deminers might be at greater risk of missing mines. Sometimes deminers will neutralize, disarm, and then inert the first landmines found on a survey or clearance task and use these as test targets for calibrating detectors. The logic behind this is that the mine will have weathered in a way consistent with other mines on that particular site and therefore provides a more faithful representation of what deminers need to detect with their Electro-Magnetic Induction equipment.8 (Specific test pieces are manufactured but they don't have the ageing characteristics of items found on site.) FFE items may also be required for research, such as the evaluation of new sensors for mine detection.9,10 While there have been efforts to develop surrogates for use in lieu of FFE items for research purposes,11-13 testing in field locations still invariably uses items immediately available, such as FFE mines, rather than surrogates that might need to be imported at significant expense.

FFE items are also needed to train HMA explosive ordnance disposal (EOD) staff, not just for recognition purposes, but also for simulated task scenarios. Such needs mirror those of military EOD units. In the United States, the Department of Defense requires Secretaries of Military Departments to “provide sufficient quantities of inert and live EO items for EOD procedures joint validation and test verification and EOD training.”14 While surrogates made by means of 3D printing are available,15 they can be expensive and may be deliberately made to be visually distinguishable from real versions that have been made FFE. Other uses of FFE items are perhaps less essential and include displays of items made FFE at various mine action organizations. Such displays may have many purposes, including as a form of exhibit to brief visitors while doubling as a training resource. FFE items are also used for museum displays.16

Current Risk Management of FFE in Mine Action

There are a range of documents detailing how FFE items should be made and certified. The documents reflect the different contexts of mine action and ammunition storage and are therefore not necessarily consistent. The current mine action guidelines on making and assessing items as FFE in mine action are detailed in International Mine Action Standard (IMAS) 10.50, “Storage, Transportation and Handling of Explosives.”17 While not a normative reference of IMAS 10.50, International Ammunition Technical Guideline (IATG) 06.50, “Specific Safety Precautions (Storage and Operations),” also has pertinent detail.18 Notably, Annex F of IMAS 10.50 details some requirements concerning the “breakdown or modification of live mines and ammunition into inert, drill, instructional or replica items,” whilst IATGs only give guidance on certifying those items as FFE.19 Breakdown of ammunition is detailed in IATG 07.30, “Ammunition Processing Operations,” but not really in the context of inerting items in order to certify them as FFE.20 This is consistent with the old UK Joint Service Publication 482 on which much IATG content is based.21 It might also be said that this reflects the different needs of each respective sector. Some may argue that mine action needs to conduct inerting procedures in a way that is not necessary for routine ammunition storage. What is clear is that a sector that conducts inerting is

carrying significant levels of risk and accordingly should have a high level of risk management practice as a norm.

Does mine action have sufficiently developed risk management procedures for making items FFE, let alone certifying items? It is not clear that it does. One significant omission from IMAS 10.50 Annex F is the lack of any form of risk assessment requirement prior to making an item FFE. Perhaps remarkably, the whole of the current IMAS 10.50 does not include the term “risk assessment” at all. IATGs do require a risk assessment prior to any explosive process, including CFFE.

While IMAS 10.50 emphasizes the need for authorization procedures, Annex F often uses the word “must” rather than “shall” when detailing requirements, which in the IMAS entails a degree of ambiguity. These requirements include the need for full technical documentation and the need for authority from the National Mine Action Centre to conduct a procedure. IMAS also states that “all authorised breakdown or modification of live mines and ammunition into inert, drill, instructional or replica items shall only be carried out by appropriately qualified and authorised personnel.”22 Which personnel in mine action are “appropriately qualified and authorized” to make items FFE, let alone certify items? It is not clear whether there is actually a specific qualification to inert items. The US Marines are often seen as leading on inerting undamaged and unfired EO. While they have an exploitation course, it is not a requirement for inerting. It tends to be done by those with the highest levels of skill and experience.23–25 IMAS 10.50 does add that only EOD Level 3+ personnel conduct demilitarization. However, at the time when the third edition of IMAS 10.50 was written in 2013, the EOD competencies did not mention demilitarization or FFE at all.

The new Test and Evaluation Protocol (T&EP) 09.30, “Conventional EOD Competency Standards,”26 tried to provide more detail on the knowledge and skills required to at least assess items as FFE. A new EOD 3+ module, Advanced Explosive Theory, listed thirty-one competencies for assessing items. Emphasis was placed on understanding in detail all energetic elements within an item of EO. Other skills listed included use of X-ray, development and maintenance of FFE register, and drafting of specific risk assessments for assessment and certification of FFE items. Unlike IMAS 10.50, the competencies covered FFE assessment only, not any form of inerting or making items FFE. At present there are no competencies that cover inerting or demilitarization even though these are activities that do occur in the sector. During the development of revised 2022 T&EP 09.30, the possibility of a specific EOD 3+ module covering demilitarization competencies was raised but was ultimately rejected. If such a module had been developed it would have been suitable only for the most advanced EOD technicians and would have involved technical training well beyond any other 3+ module. A 3+ demilitarization module would last many months, rather than just a few weeks, require strict pre-requisites for candidates, and necessitate specialized ammunition processing facilities.

Certain commercial organizations do have detailed risk management processes for demilitarization. Fenix Insight conduct demilitarization of a range of ordnance, notably cluster munitions and explosive submunitions, in order to assist countries to meet their Article 3 obligations under the Convention on Cluster Munitions.27 The nongovernmental organization (NGO) Golden West Humanitarian Foundation (GWHF) runs a demilitarization site in Cambodia where EO, once disarmed, is harvested for explosives that are then used for donor charges for demining activities.28–31 The risk management systems for explosive processing for both organizations are stringent. Each process, clearly documented, is subject to formal internal approval. Managers actively identify, manage, and own risk.

A 3D printed replica PMA-2 anti-personnel mine

FFE in the British Military

In the United Kingdom, military “CFFE is to be treated as an explosives process,”32 which implicitly requires a number of safety and risk management precautions to be observed. “Any task involving the manufacture, assembly, repair, testing, modification, or disassembly of explosives carries with it an increased risk of accidental initiation. It is therefore to be regarded as explosives processing and is to be carried out in a facility suitable for explosives processing.”33 In accordance with Army Command Standing Order 1200,34 the “implementation of Safe Systems of Work (SSOW)” is an overall framework that describes the main elements of a safety implementation when conducting an explosive process, including FFE. The key elements are competent staff, adequate supervision, suitable written work instructions, appropriate work equipment, and adequate work facilities.35 The form an SSOW takes is guided by a risk assessment that considers training needs.36 This is sometimes referred to in shorthand as “safe place, safe people and safe procedures.” Notably “staff must have appropriate written authorization indicating

The INERT item has been developed for training deminers by the Swiss EOD Center. The training aid has been designed to assist detection training, with with ability to change the metal content in the small red container. While not necessarily a perfect match for items that have weathered over time, and not an option for test pieces, such items are an option for training deminers. Figures courtesy of the author.

their competency to carry out particular tasks.”37 The process would need to be detailed by work instructions38 authorized by someone not below the rank of Major or equivalent, with an intimate knowledge of the process, who is themselves authorized by someone not below the rank of Lieutenant Colonel or equivalent.39 Personnel authorized to certify FFE are published on Unit Standing Orders, adding to transparency.40 Another means of controlling the process is the implementation of a Permit to Work system.41 Mine action does not have an equivalent.42,43 Above all these requirements, the key document on the subject, Defence Safety Agency 03. Ordnance Munitions and Explosives only details certifying items FFE. It does not describe the requirements for actually inerting items. This is because typically the process of inerting would not be done by military personal at all, but by specialists at the Defence Science and Technology Laboratory who possess the remote equipment required for this form of explosive processing. It is notable that an equivalent overarching framework for conducting FFE is not replicated in HMA.44

Should Mine Action Even Be Making Items FFE?

It could be argued that making items FFE should largely stop within the mine action sector. There are already many items that are claimed as FFE by many organizations, and these can be supplemented by inert training aids that can be produced relatively easily by means of 3D printing. If making items FFE entails a “high degree of inherent risk,” does the risk-reward calculation make sense anymore? After all, military organizations such as the British Army only inert items if it is strictly necessary. The question is at least worth asking within HMA.

Some will argue that it is justifiable to continue to inert items, not least since in certain circumstances we will continue to neutralize and disarm items of EO regardless. For some simple AP mines, the process of neutralization

Figure 4. Mechanical Remote Fuze Disassembly Kit used for removing small energetic components such as primers in fuze rotors, GWHF Cambodia 2014. If mine action organizations wish to make items of explosive ordnance INERT, and to train suitable staff to do so, specialist explosive processing facilities are required. Image courtesy of Roger Hess.

and disarming is a significant part of the inerting process anyway. At least for minefield clearance, no longer inerting items could mean not having high fidelity test pieces that reduce the risk of missed mines and also more destruction of mines in situ, potentially leading to more metal contamination and false positive signals during clearance, as well as more risk in a different sense.

In some ways inerting items of EO poses a dilemma for the mine action sector. On the one hand, the ammunition management sector sees making items FFE as a last resort, and when it is done, it must be justified by managers, and extensive levels of risk management are required. The mine action sector, used to removing explosives from items such as simple AP mines in order to make test pieces over many years, has not treated this as an explosive process but sometimes as a relatively routine field practice. Whether mine action should strictly mirror ammunition management and apply the same level of rigor is up to those who lead the sector. However, it is clear that when both certifying and inerting items, the mine action sector should review its norms and consider whether its procedures reduce risk to a level “as low as reasonably practicable” (ALARP).

Figure 5. An INERT MRV-U fuze complete. Note that the fuze appearance has been altered in order to make the item FFE. A full cut has been made above the shutter in order to gain access to the primers, stemming, and other energetic components. For some models, cuts on fuze bodies can be good initial indicators as to whether energetics have been removed and the item really is FFE. A window to view the setback sleeve has also been added during the inerting process. Making such an item FFE is an explosive process that should be conducted with a high level of risk management. Figure courtesy of Dutch EOD Center.

Possible FFE Risk Management Options to Consider

Designing a detailed and heavy risk management system for inerting and certifying FFE is an option, but any proposed system needs acceptance by the sector. The answer could be to revise the risk management system so that it is rigorous but does not overburden HMA field operators and recognizes the context of HMA demining operations. Calibrating such a system appropriately will be an important part in its success or failure. Some options to consider could include:

- All organizations maintaining a central record of all items they have certified FFE globally, respectively

- An approved, model-specific, energetic component check list for certifying each item of FFE held

- FFE certificates listing the exact energetic components removed with date, time, and individual who conducted the procedure recorded, along with detail of the permanent FFE marking

- A surveillance regime for all accidents related to FFE

- Development by each mine action organization of an overall standard operating procedure (SOP) for assessing items as FFE

- If the organization wishes to make items INERT, a list of approved technical procedures needs to be developed for each model to be made FFE. Each procedure could have two technical approvals, one of which could be independent of the organization

- If the organization wishes to make items INERT, an FFE training record that details each specific model an individual is authorized to make or certify as FFE that is time limited

- A risk assessment specific to the model of EO, primarily applicable to making items FFE but also relevant to certification

- For making an item FFE, a Permission to Work form to be completed by an authorized senior technician that confirms that a SSOW is in place for an explosive process to take place

- If an organization wishes to make items INERT, development of advanced demilitarization training.

While these options might seem basic, if just CFFE options were implemented in mine action, the risk of FFE-related incidents could be reduced. Even something as simple as the widespread development of SOPs for assessing items as FFE would be a significant step forward. For organizations that wish to make items FFE, a full review of how this can be achieved while managing risk responsibly could be advisable.

FFE Risk Assessments

If organizations wish to make items INERT, pertinent written risk assessments are an essential element of any risk management system. The key principle for an FFE risk assessment is that it must be specific, not generic, in that it

yellow elements visible in the booster section are not explosive but an inert substitute intended to indicate the position of some energetic elements within the fuze. Figure courtesy of Dutch EOD Center.

must refer to each exact energetic component contained within an item of EO. The risk assessment will also detail a control measure or risk treatment for that component. That control measure will often be the same as the specific part of the authorized process to remove that component, but the documents are not necessarily the same. The risk assessment would complement the inerting process but would not be a substitute for it.

It is notable that even for a relatively simple AP mine, the risk assessment is fairly detailed. More complex items of EO will invariably require a more detailed risk assessment, consistent with the number of energetic components they contain, and formally approved procedures required to access and remove those components.

FFE Procedure

The development of a technical procedure is an indispensable element of any FFE process, both for making and certifying an item as FFE. The procedure must not only identify each energetic component, but how it will be removed safely. NGOs such as GWHF have developed such procedure documents.45,46 It should also be sufficiently illustrated with technical photographs so that there is no ambiguity as to the information it is trying to convey. The procedure complements a risk assessment for a specific item, but it is not a substitute for one. HMA organizations should be careful that the procedure is only ever carried out by those proven competent to do so. A reasonable test for such competency, even for those with advanced EOD qualifications, would be for the EOD technician to rehearse how the procedure will be conducted without reference to the procedure document, in order to confirm understanding, prior to a Permission to Work being granted.

Environmental Considerations

Removal of energetics, particularly main charges, can lead to chemical waste such as wastewater contaminated by TNT through the process of wash out and steam out,47 or by means of hydro-abrasive cutting.48,49 Mine action has only recently started to appreciate the specific pollution risks associated with EO.50,51 Especially if large items with significant volumes of explosive fill are to be made FFE, the risk assessment should include how any specific environmental impact will be controlled. Various energetics have differing levels of toxicity. For example, Tetryl has been phased out since the 1970s due to health effects experienced by exposed munitions workers since the 1940s.52–54 It is still commonly found in legacy munitions. Chronic exposure to both RDX and TNT is known to present a degree of risk.55–57 Any inerting risk assessment should consider the potential health effects that repeated exposure to a given energetic could entail and identify the standard controls, such as use of basic personal protective equipment.

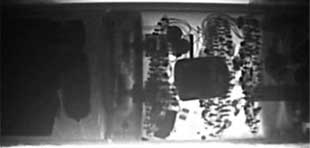

Figure 7. An X-ray of an ADSID sensor. X-rays were taken of the ADSID using a SAIC RTR-4 with the XRS-3 X-ray source; 10 pulses at 25cm for all X-rays. No detonation cord, booster, or main charge was detected in the body. X-rays are an important means of discovering whether items still contain energetic components, prior to certifying them FFE. Figure courtesy of GWHF.

Figure 8. An X-ray of a heat warhead. X-rays are an important means of discovering whether items still contain energetic components, prior to certifying them FFE. Figure courtesy of private individual.

FFE Records

HMA organizations should maintain a detailed record of all FFE items they have globally. Keeping records solely at a given location is insufficient. Such a detailed register must be more than a list of FFE certificates with accompanying FFE codes. It should detail when the item was originally made FFE, when it was certified, when it was last checked, when it must be checked again, and who has conducted all these procedures. Individual FFE certificates should also list the energetic components removed from an item. If an X-ray image was used to confirm the absence of energetics within an enclosed item (e.g., a fuze), the X-ray image should be included on the certificate, annotated to show where components are confirmed as absent. In this way instances of “assumed FFE,” such as fuzes that have been burnt, can be avoided. The record must identify where the marking of the item is positioned and whether the marking is engraved (recommended) or just indelibly marked. The security of the item should also be detailed (i.e., is the item locked away so that it cannot be mixed inadvertently with live ordnance).

Conclusion

Making and certifying items FFE are relatively unregulated activities in HMA. It might well prove that a more stringent system than the one briefly sketched here will be required at some point in the future. In any case, what is outlined in this article would be a significant increase in the current level of risk management process for FFE in mine action and can at least serve as a starting point for a long overdue discussion within the sector. Regardless of whether a new way of making and certifying items as FFE is adopted, the approach outlined in various documents concerning FFE, including IMAS 10.50, IATG 06.10, and T&EP 09.30, requires rationalization, so that at least a consistent approach can be adopted. In addition to this, each mine action operator may wish to review their FFE SOPs to ensure they are content with the levels of risk management detailed. Ultimately, each mine action organization should not only be able to identify and manage risk but actively own the risks they choose to take.

Roly Evans

Roly Evans

Advisor in Land Release and Operational Efficiency

Geneva International Centre for Humanitarian Demining

Roly Evans is an Advisor in Land Release, Operational Efficiency and Training Development at the Geneva International Centre for Humanitarian Demining where he runs the Explosive Ordnance project. He also develops IMAS, T&EPs, TNMAs and technical guides for the mine action sector. He has worked in the fields of survey, clearance, EOD, and physical security and stockpile management in Africa, Europe, the Middle East, South Asia, and Southeast Asia. He holds an MSc in Explosive Ordnance Engineering.