Helping a manufacturing giant conserve energy

Engineering students look to improve efficiency of Harrisonburg branch

Science and TechnologySUMMARY: One year into a two-year engineering capstone project, a group of rising JMU seniors is making good progress on helping a global manufacturing giant improve the energy efficiency of its Harrisonburg service center.

One year into a two-year engineering capstone project, a group of rising JMU seniors is making good progress on helping a global manufacturing giant improve the energy efficiency of its Harrisonburg service center.

Kawneer Company, Inc., a subsidiary of Alcoa, will be testing some of Alcoa's energy-saving products — thermally broken storefront, light shelves and solar shades — this summer. The products will be installed on the recommendation of four JMU engineering students — Jessica Roberts, Alex Kroll, Javal Swift and Zack Bartemy.

The project was proposed by 2013 JMU engineering alumnus Evan Bowen, who now works for Kawneer and was recently selected as the recipient of an Alcoa EarthWatch Fellow. As a Fellow, Bowen was required to propose a local project that would impact the sustainability of Alcoa/Kawneer.

Late in August 2015, Bowen visited JMU and interviewed his future team members. After meeting with him, all four students decided that the project would be their first choice when it came time for them to select their capstones.

"Working with the students has been fun," Bowen said. "I made this project because I wanted to have JMU and Kawneer partner in a way that benefitted both organizations and the local community. Working together, we've created a unique opportunity for the students where real world decisions are made based on the data they collect."

Using a thermal imager, a tool that looks almost like a large Game Boy, the group was able to identify problem areas in the building.

"The thermal imager allowed us to identify thermal leakage in the roof tiles due to poor insulation as well as thermal bridging within the walls of the building," Roberts said.

Thermal bridging occurs when an area of an object (such as a building) has a higher heat transfer than the surrounding materials. This results in an overall reduction in thermal insulation.

The group also consulted a local energy auditor, Charles Hendricks, who works for the Harrisonburg Electric Commission.

"Besides using the thermal imager to identify issues during the audit, we also conducted a blower door test to analyze the overall building leakage," Bartemy said.

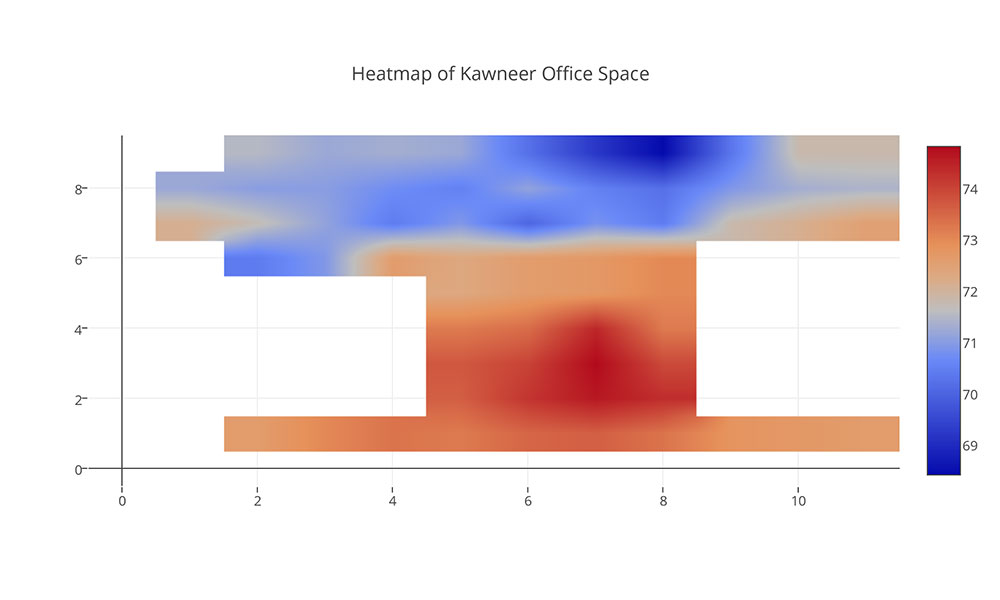

Additionally, they created a temperature gradient of the office space to analyze the uneven heat distribution within the office.

"This was created by taking temperature readings in three foot intervals and constructing the heat map dimensions to be the same as the office floor plan," Kroll said.

Thermally broken windows, which provide an insulating barrier within the frame to minimize energy transfer, should reduce energy loss from windows; light shelves will help reflect daylight into the building; and solar shades will focus on heat control, glare control and UV protection. The products will be installed in the entrance area of the building, on a window wall and in one office. Emergency lights also will be switched to LED bulbs, another suggestion from the JMU team.

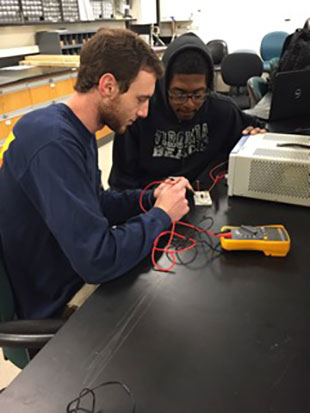

Using sensors they are building, the students will gather data before and after the renovations. Calibrated photodiodes, for example, will measure incoming sunlight and provide details on how it affects temperature. That information in turn will help with making decisions leading to more efficient use of air conditioning.

Calibrated photodiode circuits also will be used to determine the effectiveness of light shelves reducing the need for artificial light, which would also save energy.

Another sensor, called a thermocouple, will be used to measure surface temperatures on existing windows and then on thermally broken windows to compare conductive thermal energy loss between the two types of windows.

To complete their project next year, the team will make a second set of recommendations that could be implemented in 2017.

"The end goal of this is to provide Alcoa with third-party data on their products as well as provide Kawneer a return on investment on the building renovations while reducing the overall building energy consumption," Swift said.

By Rachel Petty ('17), JMU Communications