Not just a better mousetrap

Engineering major's 3-D printer will do more than print

News

SUMMARY: Richard Xu is happy to discuss his little side project -- designing and building a 3-D printer from scratch. "I could probably print a smart car if I really wanted to," he says. Don't put it past him. Moments after meeting Xu, a 6-foot-5, 275-pound Chinese-American who was an offensive lineman on JMU's national championship football team last fall, it's clear this guy probably succeeds at just about anything he puts his mind to.

from the Fall 2017 issue of Madison

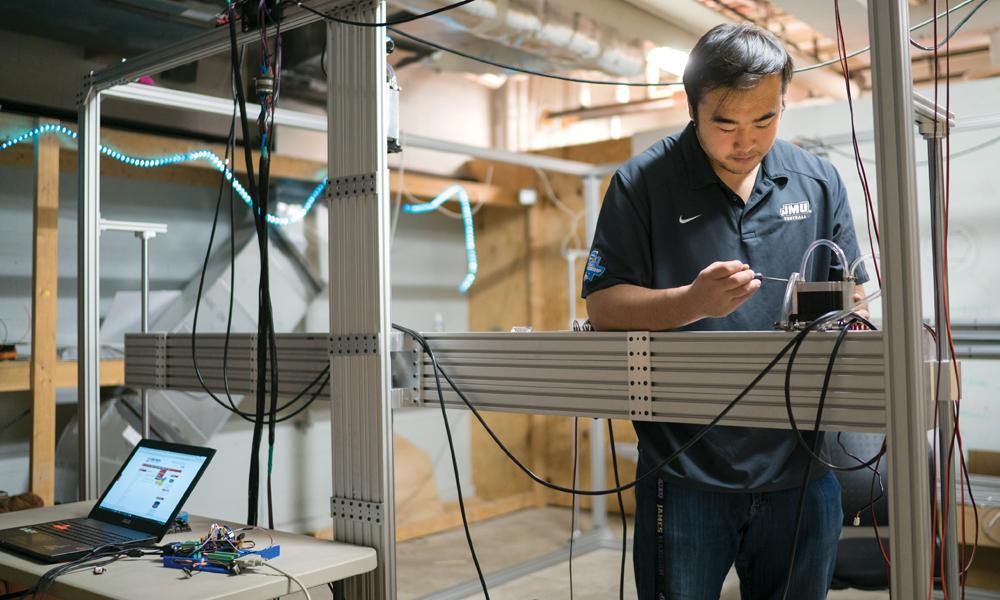

Engineering major Richard Xu is happy to discuss his little side project — designing and building a 3-D printer from scratch.

Just be prepared, if you’re not fluent in electronics or mechanical terms, to look some things up. Within seconds he’ll talk about wanting a “pick-and-place.” And in order to make a PCB, he needs a CNC machine. The 6-foot-5, 275-pound Chinese-American — an offensive lineman on JMU’s national championship football team last fall — goes on to explain, “I have motor controls that go into gantries, and then I have a 12-volt rail with a live rail that does all the other power management. I have a signal cable that goes in there and at the end of the day, all I do is swap stuff out.”

You see, this won’t be just any 3-D printer. It will be bigger than most, more accurate than most and do more than just print. “I could probably print a smart car if I really wanted to,” says Xu (pronounced “shuh”).

Don’t put it past him. Moments after meeting Xu, it’s clear this guy probably succeeds at just about anything he puts his mind to. During the Fall 2016 semester, with football in full swing, Xu took 22 credit hours. “My mom told me I couldn't take 22 credit hours and pass all my classes. I passed them all. … A lot of all-nighters and stuff like that.”

|

| Xu with members of the Dukes football team during a spring practice |

Xu, a rising senior, won’t have to manage that kind of schedule moving forward. He decided to “retire” from football this summer due to nagging injuries.

The 3-D printer is not even part of a class project. It’s just something he decided he wanted to do. “I'm a big-circuits guy,” he says (no pun intended). “I like making little gizmos and stuff.” But the parts needed for making little gizmos and stuff can cost big money. Plus, a regular 3-D printer could do some of the things he wanted to do, but there were other things that required different machines.

“I realized after looking at designs of pick-and-places and CNCs and everything else, they really just run on the same machine. It's just different methods. … It just came to me, why hasn’t anybody done this?”

|

'I realized after looking at designs of pick-and-places and CNCs and everything else, they really just run on the same machine. It's just different methods. … It just came to me, why hasn’t anybody done this?' |

Xu is financing most of the project with money his parents saved to send him to college. Since he received nearly a full scholarship to play football, the money is now going into his project. He fully intends to pay them back with the profits he earns once he starts selling the machine. A local company has already expressed interest in it.

Xu and his business partners, College of Business students Chris Ashley (’17) and Bryce Edmunds, received a $10,000 grant to participate in the eight-week Venture Creation Fellowship, a summer accelerator program hosted by the Center for Entrepreneurship.

“Richard has a great mind for envisioning how systems work and how to build out those visions,” says Ashley, an economics major who met Xu in the summer of 2016 at X-Labs, JMU’s maker space in Lakeview Hall. “I’m excited to work on a team with him.”

|

| (L-R) Bryce Edmunds, Xu and Chris Ashley are building the 3-D printer at X-Labs, a maker space in Lakeview Hall. |

All eight Venture Creation teams worked on their projects in June and July in the JMU Technology Innovation offices in the Ice House. Participants spent some of their time meeting with and hearing from patent lawyers, venture capitalists and entrepreneurs, who shared advice and insight into launching a company. “We also had some more structured workshops for topics such as market research techniques and building a pitch deck,” Ashley says.

While Xu is not earning academic credit for the 3-D printer project, he says it is helping him with his studies. “I hate doing problems and stuff. I’m more of a hands-on learner, so this project is kind of why I'm passing all my classes right now,” he says. “I need to apply it on something that is realistic.”

He also plans to use it to print a drone for his engineering capstone project, which involves attaching sensors to a drone to create elevation models needed to predict flooding in low-lying coastal areas.

|

'Do you really need to drive to Home Depot, wait in line, find a trashcan? You just print one out.' |

In the long run, Xu hopes his printer—or "micro factory"—becomes a household item as common as a kitchen appliance. "If something breaks in the house, instead of going to find that part, companies can offer STLs (STereoLithography). Just print them out and then your part is right there, you don't have to go anywhere. Some simpler things, like trashcans. Do you really need to drive to Home Depot, wait in line, find a trashcan? You just print one out."

Future improvements, he says, will enable the machine to print glass filaments and medical items. "Plasma cutting is going in too. I don’t know anything we can’t do with this machine. The motto is, find something we can’t do with this machine, figure out how to do it, then find something else we can’t do.”